Steel Dock sleeves

Steel pontoon docks are great…until they aren’t!

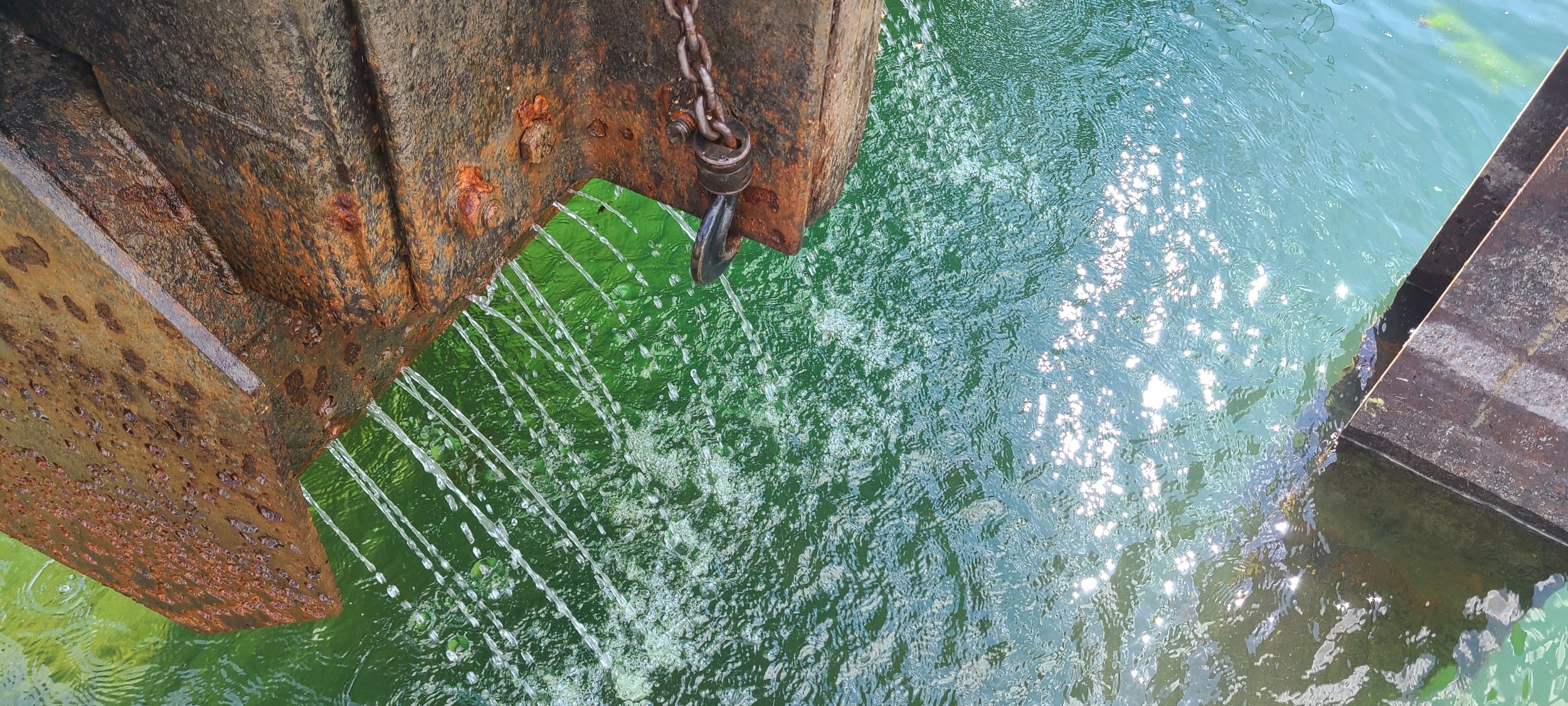

For years, municipal and commercial marinas have been installing steel floating docks on steel pipe floatation. They are a structurally strong dock, with robust connections and heavy anchor points. They are extremely expensive, and even with the best quality paints and coatings, they inevitably rust.

While the structure above water is still in good condition, the portion of the steel pontoons that are underwater typically begin to rust through and sink between 20 and 25 years after installation.

Replacement can be cost-prohibitive, and band-aid repairs are temporary at best. Filling the pipes with foam only lasts a few years before the foam loses buoyancy, and it pollutes our waterways with leaching chemicals. The foam cannot be removed, so the docks need to be disposed of when the foam fails.

Pipefusion/Nydock and Gardiner Marine have the best possible solution to breath new life into your aging steel dock system. The steel pontoon is cut open at one end, and a slightly smaller diameter HDPE pipefusion “sleeve” (a sealed dock pontoon, but smooth with no tabs), is inserted into the hollow steel pipe. This displaces almost 90% of the original volume of the steel pipes, making the docks sit only slightly lower in the water. The steel pipe end is then welded back in place, simply to encapsulate the sleeve (there is no need for it to be watertight anymore).

The sleeves carry the lifetime Pipefusion pontoon warranty, and have an almost unlimited life expectancy. Your steel docks should continue to provide excellent service for decades after this repair.